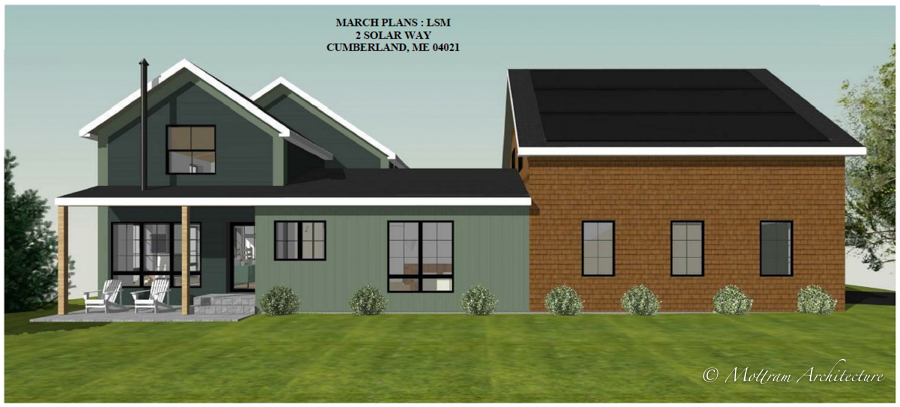

You may or may not have seen that Bensonwood is rolling out a new division of their company called Tektoniks where they are combining their knowledge from Bensonwood and Unity homes to help supply the market with something it desperately needs: Better Homes with Panelized ConstructionPrefab, modular and panelized construction has gotten a bad name over the years. People often associate it with low quality housing, but that's not really the case. Look back to the start of kit housing and the Sears catalog and you'll see that they sold over 70,000 homes between 1902 and 1940. The kit of parts was delivered to the site and often raised in a "barn raising" type style. It supplied a need for housing in the country that was quick and affordable. And to be honest, pretty stylish.Somewhere along the lines we lost some of that stylish design, the adherence to quality, and the ability to move forward in the building industry building BETTER homes, not just cheaper homes.But I digress, what does panelized construction have to do with today's housing needs? As an architect working with zero energy and super insulated houses, I find panelized construction fascinating. We've been using it on one of our developments in Maine for the last several years. We started with a framer that builds the walls in a shop, delivers them to the site, and 3 days later we have a shell. Framing them in the shop cuts down on time, often taking a 9-12 month build down to 6 months. The quality control and material control can cut waste and job site debris down by almost 25%. And when you're building indoors, weather delays aren't an issue. So while the site is being prepped, framing is happening at the same time. But our framer, he's busy. I wish we had 2 or 3 more to help with construction right now.But how are they different? Why is this different than SIPS panels or modular construction? These are prototypes of zero energy homes. We spend hours in design development working out the systems to cut down on thermal bridging, orient the home the right direction, and provide really great spaces. We are very strict about the materials we use cutting out as much foams, plastics, and formaldehyde products. They are custom homes where we eliminate as much square footage as possible while still spending the time to make spacious areas and a spot for everything. More square footage isn't better, it's just more. In a world where we are seeing people going back to their roots, wanting less, spending more time outside of the home or in a community, this seems like the right answer. Minimizing the impact of building, the buildings impact on environment, and most importantly celebrating it's impact on the occupants. Our health and welfare can be directly linked to where we live.So why aren't we building better? Well the answer is, here at Mottram Architecture, we are.Stay tuned for updates on how the next Live Solar Maine house is going:

We started with a framer that builds the walls in a shop, delivers them to the site, and 3 days later we have a shell. Framing them in the shop cuts down on time, often taking a 9-12 month build down to 6 months. The quality control and material control can cut waste and job site debris down by almost 25%. And when you're building indoors, weather delays aren't an issue. So while the site is being prepped, framing is happening at the same time. But our framer, he's busy. I wish we had 2 or 3 more to help with construction right now.But how are they different? Why is this different than SIPS panels or modular construction? These are prototypes of zero energy homes. We spend hours in design development working out the systems to cut down on thermal bridging, orient the home the right direction, and provide really great spaces. We are very strict about the materials we use cutting out as much foams, plastics, and formaldehyde products. They are custom homes where we eliminate as much square footage as possible while still spending the time to make spacious areas and a spot for everything. More square footage isn't better, it's just more. In a world where we are seeing people going back to their roots, wanting less, spending more time outside of the home or in a community, this seems like the right answer. Minimizing the impact of building, the buildings impact on environment, and most importantly celebrating it's impact on the occupants. Our health and welfare can be directly linked to where we live.So why aren't we building better? Well the answer is, here at Mottram Architecture, we are.Stay tuned for updates on how the next Live Solar Maine house is going: